New German technology uses foam ceramics and UV LEDs to break down industrial contaminants before they reach the water.

- Resistant contaminants in industrial water.

- Photocatalytic foam ceramics.

- UV light to degrade organic compounds.

- No additional chemicals.

- High energy efficiency.

- Real-world pilot projects in key industries.

- Scalable and adaptable technology.

Water purification with light: a new generation of compact and efficient water treatment systems

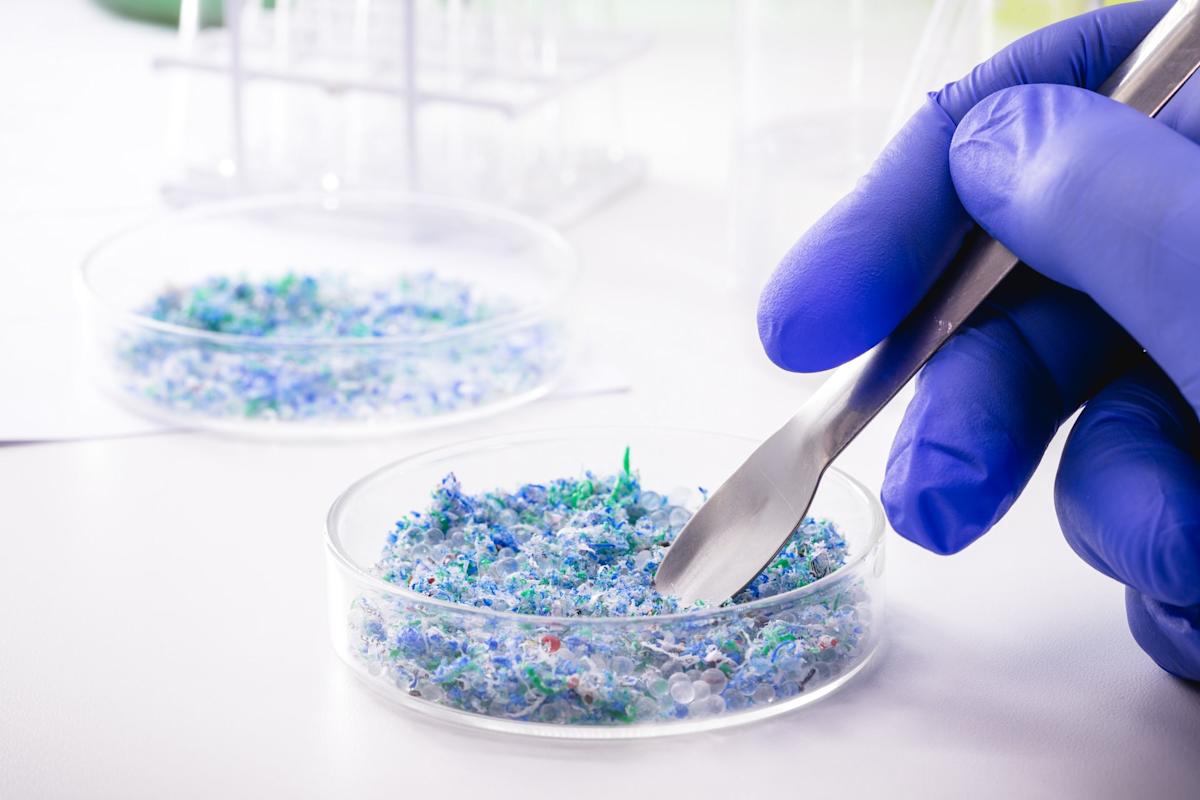

Industrial wastewater treatment remains one of the greatest environmental challenges of our time. Although modern treatment plants exist, persistent pollutants continue to escape control. Pesticides, microplastics, PFAS, dyes and pharmaceuticals end up in rivers, aquifers and, eventually, in our taps. These substances, many of which are classified as endocrine disruptors or potential carcinogens, accumulate in ecosystems without degrading easily.

Current solutions, such as biological treatment or advanced filtration, do not always manage to eliminate them completely. Furthermore, their operation can be costly, slow or generate secondary waste. This forces us to rethink our approach, especially in sectors with high pollution loads such as the pharmaceutical, chemical, textile and processed food industries.

Ceramic technology with light: an innovative response

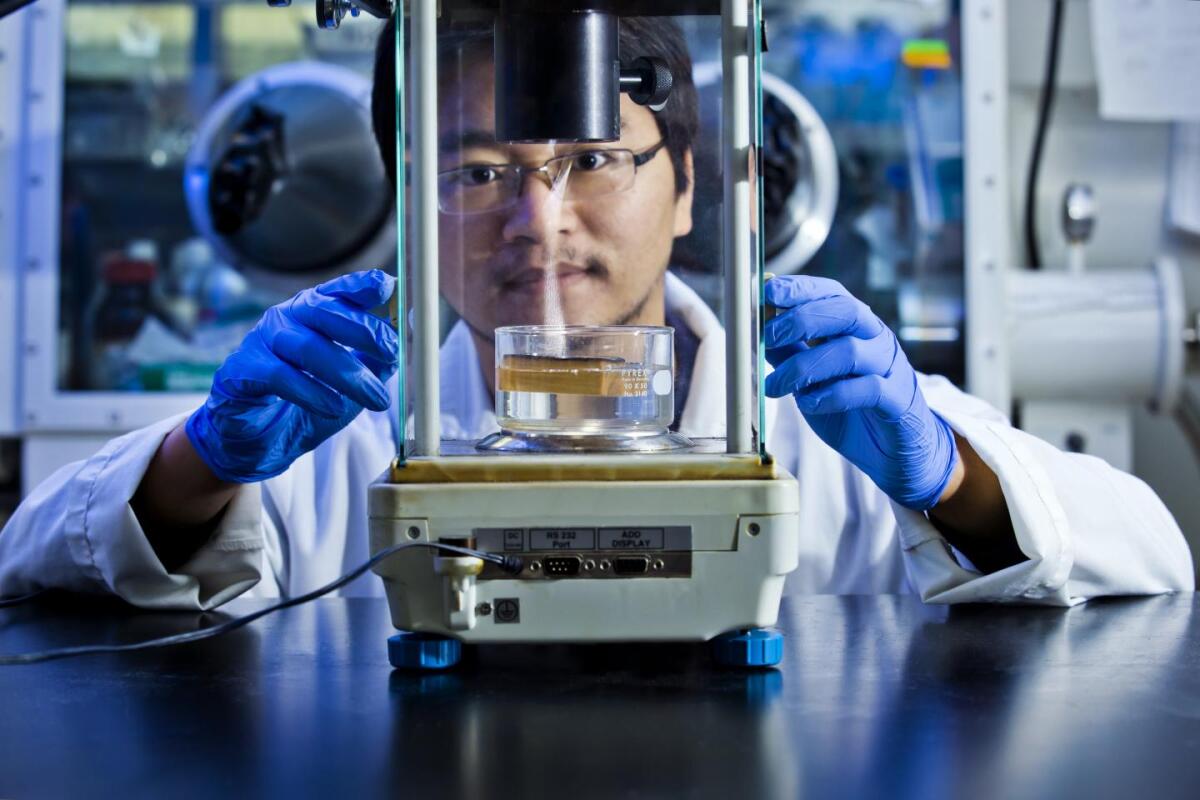

The Fraunhofer IKTS Institute in Dresden has taken a firm step towards an efficient and sustainable solution. They have developed multifunctional foam ceramics that act as platforms for photocatalytic oxidation processes, capable of destroying pollutants at the molecular level.

The key lies in combining materials with advanced catalytic properties and a highly reactive porous structure, exposed to ultraviolet (UV) light. This system generates free radicals — especially hydroxyls — that break complex chemical bonds, without the need to add toxic compounds or produce additional waste.

The result: a clean, quiet and adaptable process that eliminates problematic molecules without generating polluting by-products.

What makes this technology unique?

- Energy efficiency: By using low-power UV LEDs and optimising the reactor geometry, the system maximises the interaction between light, contaminant and catalyst.

- High reactive surface area: Ceramic foams offer porosity of up to 90%, which exponentially increases the usable reaction surface area compared to other traditional supports.

- Stability and durability: The catalysts are robustly fixed to the ceramic structure, preventing their release into the treated water.

- Modularity: Each system can be adapted to different flow rates, types of pollutants and industrial conditions, without the need to redesign the entire existing infrastructure.

Real-world applications and pilot tests

Several sectors are currently testing this technology directly in their facilities. In particular, companies in the pharmaceutical, semiconductor and textile sectors, where the generation of highly stable pollutants is a constant problem.

In one of the most significant pilot projects, a paper mill in Germany has managed to reduce the concentration of non-biodegradable organic compounds by more than 85% before discharge. Other trials in the dairy industry have shown positive results in the elimination of hormone and antibiotic residues.

In addition, this type of solution allows for on-site treatment, which avoids the transport of large volumes of contaminated water to central stations, with the consequent savings in energy, logistics and emissions.

Implications beyond the industrial sector

Although this technology has been designed with industrial processes in mind, its potential goes beyond. It can be applied in rural areas with limited access to advanced treatment systems, in climate emergency contexts where drinking water is scarce, or even as a complement to urban treatment plants, helping to meet stricter quality standards.

The European Commission and several environmental agencies are currently reviewing regulations on the presence of trace substances in wastewater. Technologies such as this could become key to meeting future legal requirements, without companies having to bear prohibitive costs.

Potential

This new generation of treatment systems represents a powerful tool against water pollution, and its large-scale adoption could bring significant benefits:

- Direct reduction of persistent pollutants in water sources.

- Better protection for aquatic biodiversity, which is highly sensitive to chemical traces.

- Greater water resilience in drought-affected regions by facilitating the reuse of treated water.

- Proactive compliance with environmental regulations, better positioning industries in the face of increasingly demanding regulatory frameworks.

- Stimulation of technological innovation around materials, clean energy and decentralised treatment.

In a world where clean water is becoming increasingly scarce, investing in compact, scalable and sustainable solutions such as this is not an option, but an urgent necessity. The combination of materials science, energy efficiency and environmental vision demonstrates that another way of treating water — one that is more respectful of the planet — is not only possible, but already a reality in the making.